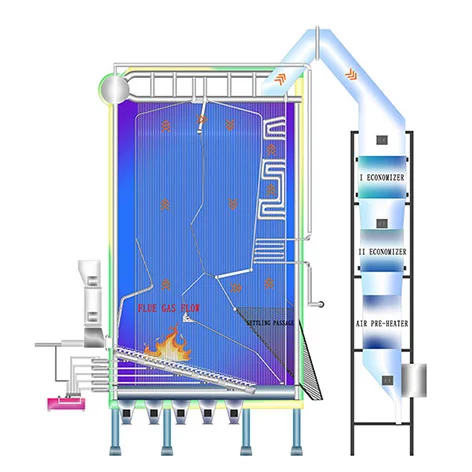

BRIT’s Four Passes Flue Gas Technology

BRIT adopts advanced 4 passes flue gas technology on its biomass fired steam boilers. Such innovation reduces the initial emissions of NOx, CO and soot significantly. It can also prevent ash deposition and lower the risk of boiler agglomerating. Here are the structural analysis below.

Furnace: Through unique coordination technique between boiler arch & fuel wind, our novel combustion technology combining layer combustion with chamber combustion can make boiler’s initial NOx emission less than 150mg/m³, initial CO emission less than 100mg/m³ with no black smoke eliminating.

2nd Pass: Unique empty load design; Complete fuel combustion reduces fly ash carbon content; Settling effect reduces initial smoke & dust content (<600mg/m³).

3rd Pass: The equal flue gas velocity design at dense heating surface reduces local resistance, prevents ash deposition due to low flue gas velocity at the end.

4th Pass: Soot blowers are installed in different areas of heat recovery surface to prevent ash deposition effectively.

Brit’s four passes flue gas technology can also prevent ash deposition and lower the risk of boiler agglomerating. We shall expand in details in another article.

To know more about us, you can visit our group website at http://www.ahbrt.com